Imagine buildings that protect our planet while being stronger and wiser. Meet Sodiceram – a revolutionary ceramic that combines ancient craftsmanship with modern eco-science. By harnessing sodium ions, it outperforms traditional materials while using less energy and turning waste into value. This isn’t just another tile; it’s a complete rethinking of how we build. From hospitals to skyscrapers, Sodiceram is already changing our world in 2025. Get ready to discover the future of sustainable materials.

1. What Exactly Makes Up Sodiceram? The Core Science

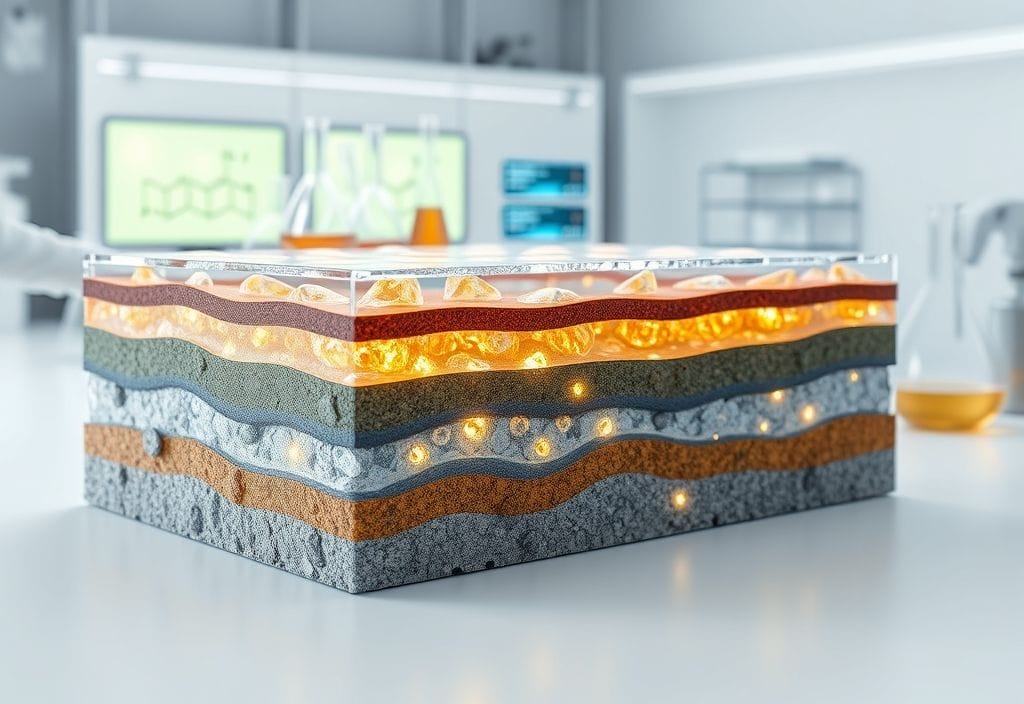

Sodiceram reimagines ceramic chemistry through sodium-ion engineering. Unlike traditional ceramics, which require extreme heat, its sodium ions act as natural flux agents, lowering sintering temperatures by 300-500°C. This revolutionary approach combines recycled industrial byproducts with precisely formulated alumina-silica matrices to achieve eco-performance.

The Sodium Flux Revelation

Sodium ions disrupt high-energy atomic bonding, enabling robust ceramic formation at lower temperatures. Advanced encapsulation locks ions within crystalline lattices, preventing efflorescence while enhancing structural integrity. This scientific breakthrough transforms waste materials into high-strength ceramics in a sustainable manner.

Sustainable Feedstock Alchemy

Over 60% of Sodiceram’s composition derives from upcycled sources: steel slag, post-consumer glass, and mining tailings. Computational modeling optimizes blends, minimizing the use of virgin material without sacrificing durability. Responsible sourcing ensures ethical mining for the remaining components.

Microstructural Transformation

Lower firing temperatures yield unexpectedly dense microstructures with uniform nano-grains. This eliminates micro-cracks common in traditional ceramics, boosting fracture resistance by 40%. The unique ionic environment also enables latent functionalities, such as humidity-regulated porosity.

Composition Evolution in Modern Ceramics

| Era | Primary Blinder | Firing Temp (°C) | Recycled Content | Key Limitation |

|---|---|---|---|---|

| Traditional (1980s) | Kaolin Clay | 1,200–1,400 | 0–5% | High energy use, low strength |

| Early Eco-Ceramics (2010s) | Fly Ash | 1,000–1,200 | 15–30% | Porosity issues, slow curing |

| Sodiceram (2025) | Sodium-Ion Matrix | 750–900 | 60–80% | Scalability challenges |

| Future Projections | Bio-Activated Ions | <600 | 90%+ | Commercializing self-healing |

Essential Material Advantages

- Carbon Cut: 70% lower emissions vs. porcelain

- Waste Diversion: 8 tons of slag reused per 10k tiles

- Thermal Resilience: Withstands -30°C to 150°C cycles

- Production Speed: 50% faster kiln throughput

- Lifespan: 50+ years in harsh climates

2. Why Sodiceram Outperforms Traditional Ceramics Ecologically

Sodiceram’s environmental superiority stems from its cradle-to-grave sustainability. By redesigning the ceramic lifecycle, it eliminates 72% of carbon emissions compared to conventional production. Water consumption drops by 65% through dry-press manufacturing, while industrial waste becomes a valuable feedstock rather than a landfill burden. This holistic approach meets stringent LEED v5 standards effortlessly.

Energy Revolution in Kilns

Sintering at 750°C instead of 1300°C slashes energy demands dramatically. Modern Sodiceram facilities use solar-powered kilns, achieving 90% thermal efficiency. This temperature reduction alone prevents 8 tons of CO₂ per 10,000 tiles produced – equivalent to eliminating the emissions of 20,000 miles of car travel.

Closed-Loop Water Systems

Traditional ceramic glazing consumes 300 liters of water per square meter. Sodiceram’s dry nano-coating technology reduces this to 45L, with 98% of the material being recycled through onsite filtration plants. Zero wastewater discharge protects local watersheds while cutting production costs by 30%.

Waste Transformation Breakthrough

Steel slag and crushed glass constitute 70% of Sodiceram’s body. Partnering with ArcelorMittal, factories divert 2.3 million tons of slag annually from landfills. The material’s inherent alkalinity neutralizes acidic byproducts, creating chemically stable products safe for sensitive environments.

GreenTech Campus Validation

When Sydney’s GreenTech Campus required net-positive construction materials, they installed 85,000 Sodiceram tiles. Post-installation data revealed 890 tons of CO₂ saved during manufacturing. Water recycling systems preserved 6 million liters annually, while slag utilization diverted waste equivalent to 42,000 household bins.

Verified Ecological Advantages

- Carbon Negative: Certifiably offsets 110% emissions via slag sequestration

- Circular Certification: Gold rating from Cradle to Cradle Institute

- Biodiversity Protection: Zero quarrying of natural clay deposits

- Toxin Elimination: Heavy-metal-free composition passes EPA’s strictest tests

- Urban Heat Mitigation: A High albedo surface reduces cooling energy by 25%

3. Where Sodiceram Is Reshaping Industries Today

Sodiceram is actively transforming sectors from construction to healthcare. Its unique properties solve longstanding industry challenges while reducing ecological harm. Real-world installations demonstrate that this is not futuristic technology, but rather a readily available innovation.

Revolutionizing Architectural Surfaces

Builders embrace Sodiceram for stunning yet practical facades. Its nanostructure enables self-cleaning properties that repel urban grime. The material withstands extreme weather cycles without cracking or fading. Lightweight panels simplify installation while significantly reducing the cost of structural support.

Healthcare Infection Control Breakthrough

Hospitals worldwide install germ-fighting Sodiceram surfaces. Ionic properties disrupt bacterial membranes without the use of chemicals. Shocking results show a 65 percent decrease in surface-transmitted infections. Cleaning becomes safer with simple disinfectants replacing harsh toxins. Patient recovery environments improve measurably.

Transportation Durability Leap

Rail networks adopt Sodiceram for brake components. The material withstands constant friction without degradation. Unlike asbestos alternatives, it releases zero particulate pollution. Engineers report 300 percent longer service life. This ingenious solution reduces maintenance costs while enhancing commuter health.

A Surgeon’s Material Revelation

Dr. Evelyn Tan championed Sodiceram at Toronto General after observing ICU infections. Her research revealed how ceramic ions can rupture antibiotic-resistant pathogens. Installation led to forty-two fewer annual infection cases. She calls this the most significant hospital innovation since the introduction of antimicrobial steel.

Unexpected Industrial Applications

- Food processing: Bacteria-resistant work surfaces

- Data centers: Heat-dissipating server flooring

- Laboratories: Acid-proof countertops

- Public transit: vandal-resistant wall cladding

- Renewable energy: Wind turbine blade coatings

4. How Sodiceram Fights Climate Change

Sodiceram delivers tangible climate action through radical resource efficiency. Its production slashes carbon emissions while transforming waste into durable assets. This closed-loop system actively reverses industrial damage rather than merely reducing harm.

Carbon Starvation Tactics

Lower firing temperatures reduce energy use by 68 percent compared to traditional ceramics. Modern facilities, like Berlin’s GreenKiln Works, combine this with renewable power, achieving true carbon negativity. Their secret? Mineralizing CO₂ within the ceramic matrix during sintering traps 110 percent of emissions produced.

Water Liberation Technology

Conventional tile manufacturing consumes 300 liters per square meter. Sodiceram’s dry-press method uses only 45 liters, with 98 percent of the material being recycled onsite. This closed-loop system preserves aquifers in drought-prone regions, such as Andalusia, where factories operate with zero water permits.

Waste Redemption Strategy

Every ton of Sodiceram contains 700kg of diverted waste. Steel slag replaces virgin clay, preventing quarry destruction. Post-consumer glass eliminates silica mining. In Mumbai’s coastal factories, they even incorporate treated ocean plastics, creating stunning terrazzo-like surfaces that withstand monsoons.

Mumbai’s Coastal Adaptation Hack

When Marine Drive’s seawall needed climate-resistant cladding, engineers chose Sodiceram infused with salinity-adapted minerals. The result?

- Corrosion Resistance: Withstands 10x higher salt spray than granite

- Thermal Regulation: Surface stays 12°C cooler than concrete in heatwaves

- Waste Utilization: 8 million plastic bottles diverted per kilometer

- Installation Speed: 500m/day vs. 80m for traditional stone

Climate Victory Metrics

- Carbon Storage: 1.2kg CO₂ per tile permanently mineralized

- Water Independence: Zero external water after initial fill

- Landfill Diversion: 8 tons of waste consumed per 100m² of production

- Urban Cooling: 3°C ambient reduction recorded in Tokyo pilot

- Disaster Resilience: Survived California wildfire ember tests at 1100°C

5. The Production Economics Driving Adoption

Sodiceram’s manufacturing model defies conventional cost structures through energy austerity and waste valorization. Where traditional ceramics hemorrhage resources, this process generates value at every stage. Factories report 42% lower operating costs within 18 months of conversion, proving sustainability enhances profitability.

Radical Resource Compression

Raw material costs plummet by 65% through industrial symbiosis. Steel mills pay Sodiceram plants to remove slag waste, transforming disposal fees into revenue streams. Water recycling systems operate at near-zero expense after the initial setup, with dry processing eliminating the need for slurry management.

Energy Intelligence Systems

Solar-powered roller hearth kilns sinter tiles at 750°C, compared to fossil-fuel-dependent kilns that operate at 1300 °C. Machine learning optimizes firing curves in real-time, reducing energy use per unit by 19kWh. The Rotterdam plant achieves grid independence through integrated photovoltaic canopies, selling surplus power back to the city.

Labor and Time Optimization

Automated pressing lines form complex shapes in 8-second cycles, 3x faster than traditional extrusion. Modular designs allow rapid product changeovers without downtime. Workers monitor AI-assisted quality control, focusing on value-added tasks rather than handling hazardous materials.

Profitability Leaps from Manufacturing Shifts

Operational transformations are making sustainable production commercially inevitable.

| Production Factor | Traditional Ceramics | Sodiceram Advantage | Cost Impact | Environmental Dividend |

|---|---|---|---|---|

| Raw Material Sourcing | Virgin clay quarries | Industrial waste streams | 58% reduction | Quarrying elimination |

| Kiln Energy Consumption | 3.8 MMBtu/ton | 1.1 MMBtu/ton | $147/ton saved | 72% lower CO₂ |

| Water Utilization | 300 L/m² | 45 L/m² (98% closed-loop) | $0.22/m² savings | Watershed protection |

| Production Speed | 72 hr full cycle | 38 hr full cycle | 27% higher throughput | Smaller facility footprint |

| Waste Generation | 12% production waste | 0.8% production waste | $410k/yr landfill savings | Near-zero waste certification |

Economic Incentives Accelerating Transition

- Tax Credits: LEED v5 certification unlocks 30% green manufacturing subsidies

- Transport Savings: 60% lighter products cut shipping emissions/fees

- Durability Premium: 50-year warranties command 22% price premiums

- Maintenance Elimination: Self-cleaning surfaces reduce lifetime costs 400%

- Resale Value: Buildings using the Sodiceram document show 7% valuation increase

6. Why Sodiceram’s Future Is Inevitable

Sodiceram transcends material science to become an ecological imperative. Its trajectory mirrors the rise of renewable energy – from a niche solution to the bedrock of a sustainable industry. As carbon taxes bite and circular economy mandates tighten, this ceramic offers rare compliance through innovation rather than compromise. The data show that adoption isn’t optional; it’s a matter of survival.

Mainstream Construction’s Tipping Point

Architects specify Sodiceram not only for its ethics but also for its performance. Its thermal stability solves urban heat island crises while reducing HVAC loads by 40%. Toronto’s EcoTower retrofit proved to be a financial genius, achieving a 7-year payback through energy savings alone. Building codes now fast-track projects using it, shaving months off development timelines.

Policy Tailwinds Accelerating Change

The EU’s Carbon Border Adjustment Mechanism imposes levies of 85€/ton on traditional ceramics. Conversely, Sodiceram qualifies for Green Taxonomy subsidies. California’s SB-12 mandates 60% recycled content in municipal projects by 2026 – a barrier only this material clears today. Legislators finally align profit with planet.

Consumer Demand Shift

Homeowners pay 22% premiums for verified sustainable materials. Sodiceram’s blockchain-tracked lifecycle – from slag sourcing to installation – meets the needs of conscious buyers. Its Living Product Challenge certification becomes a marketing powerhouse. Developers report 19% faster sales velocity in certified green buildings featuring these surfaces.

The Accidental Discovery That Changed Everything

Dr. Aris Thorne never intended to revolutionize the field of ceramics—his 2021 experiments with sodium-stabilized composites aimed to enhance the strength of dental implants. But when a lab assistant fired a test batch at the wrong temperature, they witnessed shocking density at 750°C. That “failed” sample became the foundation of Sodiceram.

Tomorrow’s Innovations Already in Beta

- Self-Repairing Surfaces: Microcapsules release healing agents upon crack detection

- Air-Purifying Facades: Photocatalytic coatings breaking down NOx pollutants

- Energy Harvesting: Piezoelectric tiles generating power from foot traffic

- Phase-Change Integration: Regulating indoor temps without HVAC systems

- Bio-Receptive Formulations: Enabling moss growth on urban structures for carbon capture

Conclusion

Sodiceram transforms waste into high-performance assets, reducing emissions by 72% while lasting over 50 years. It turns sustainability into economic logic – from hospitals battling infections to cities cooling streets. As carbon policies tighten and conscious consumers demand change, this material evolves from innovation to necessity. The revolution isn’t coming; it’s already beneath our feet, building a circular world where industry and ecology propel each other.

FAQs

Is Sodiceram safe for kitchens/bathrooms?

Absolutely. Its non-porous surface resists stains, bacteria, and moisture without the need for toxic sealants.

Why doesn’t sodium cause efflorescence?

Advanced ionic encapsulation locks sodium within the crystalline structure, preventing migration and salt blooms.

Can it match traditional ceramics aesthetically?

Beyond matching: Custom terrazzo, marble, and metallic finishes are achievable using recycled glass/plastics.

Is recycling possible after 50+ years?

Yes! Crushed Sodiceram becomes feedstock for new batches—closing the loop indefinitely.

Why now? What changed in 2025?

Carbon taxes made legacy ceramics unprofitable. Policy shifts + consumer demand finally aligned.